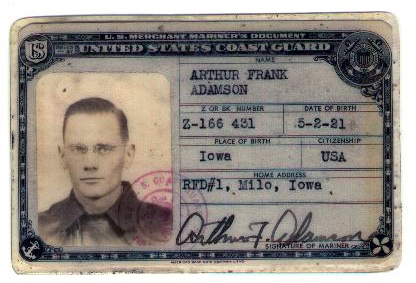

I, Arthur Frank Adamson, was born on May 2, 1921 to Arthur T. and Isa Edna Adamson. I was the first of eleven children, lived on this small farm in Iowa, Warren County, local name of hamlet "Motor."

After high school and one year of college (Wm Penn, Oskaloosa, IA) I joined the Merchant Marine and engaged in costal shipping of powdered coal. I had planned to return to college, but Pearl Harbor brought a change of plans and I signed on to a naval supply vessel, the M V Roamer, as electrician. It was a powerful and swift vessel bearing one anti aircraft gun aft and depth charges.

We began a voyage from New York with supplies for beleagered Australia (then being attacked by Japan on its North coast.) We were the only ship that escaped the German subs along our Atlantic coast (which sunk all oil tankers in sight--we watched seaman burning in oil with tears that made it difficult to operate.)

By means of speed, maneuvers, and depth charges, we made it to the Panama Canal and across the Pacific to Australia, miraculously arriving in Brisbane where we dischaged some of our cargo, then south and around Australia with our supplies. From there we went to New Zealand and operated as a supply ship to the Pacific theatre. After our ship was damaged and abandoned for repairs at Mechanic's Bay New Zealand, I was returned to USA and from there was exclusively on Liberty Ships being massively produced and always depending of safety being escorted in convoys (heaven help, could not help those left behind, which happened too often!)

Liberty Ships were a significant factor in the victory against Germany and Japan. They were mass produced based on engineering techniques developed in Scotland, a hundred years previously. Reciprocating steam engines, oiled by hand, and designed to maximase cargo space. The cooky cutter production left some vulnaribility so that errors contributed to the "left behind" problem when not able to keep with a convoy. The greatest problem was in the boilers which contain tubes so that the water is heated as it passes through oil burning flames. Due to heating and cooling expansion, the tubes can not be welded in place. Instead, they are "rolled" in to place in holes in the boiler ends. Believe it or not, the rolling is done (or should have been done) until they are able to be leak proof. Every now and then, one of two boilers had to be shut down and the tubes re-rolled with a hand operated conical device. If this was done at sea with depth charges all around, it was an awsome experience. If unsuccessful and one is left behind, it is worse than awsome.

Another danger was from cargo shift during storms. Tanks, oil drums, planes, etc. lashed to the deck may come loose and become missles. My only personal injury in the war came from being hit by a loose oil drum during an Atlantic storm which sent me to the Marine hospital for a while.

The other hazards (unknown at the time) had to do with unheathly environment and practices. Steam pipes were insulated with an asbestus compound which was knocked off with a hammer if repairs were needed, filling the air with dust. Electric components were rinsed in open vats of carbon tet. and many of my shipmates report lifetime negative results. Cigarette smokers apparently had the most difficulty from a combination of smoke and asbestus. I did not smoke and that may account for no problem with asbestus, as I breathed a lot of it.

All of my experience with seafaring after the Australian venture was with Liberty ships, except her last one which was a "Victory" ship, a somewhat improved model and it involved bring troops and brides home from Europe.

I received service medals and citations for participation in the Pacific, Atlantic, Mediterranean, and Middle East War Zones. The latter involved trips to Basra (Persia, now Iran) where a British base collected what we brought for transport to Russia by trucks which awaited eagerly every bit of supplies in their heroic battle against the Nazi's.

~Sincerely, A. Frank Adamson

![]()